How it Works

Liquid crystal materials are widely used in projectors and LC Displays (LCDs). Despite their confusing names, liquid crystals are not crystals floating in a liquid, they are elongated molecules that are naturally aligned in the same direction. The LensVector lens is composed of two glass substrates separated by spacers and sealed to contain the liquid crystal material, essentially forming a liquid crystal sandwich. When an electric field is applied to the lens, the liquid crystal molecules change orientation and cause light passing through the lens to be refocused. By managing the electrical field and the orientation of the liquid crystal molecules, it is possible to shape the beam of light.

Controlling the Lens

The LensVector lens is control system agnostic. The control solution can be wired or wireless and can utilize any of the common protocols including Bluetooth, DALI, 0-10V etc… An android or IOS app, like those from Casambi, can be used to adjust the beam size on-demand.

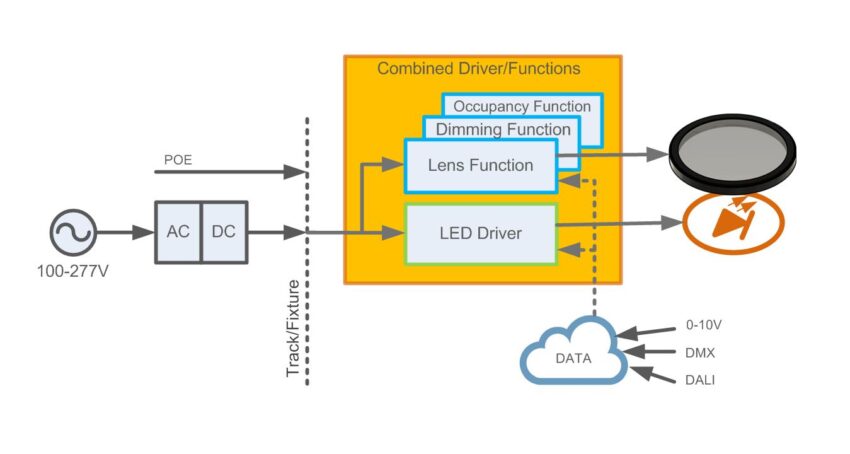

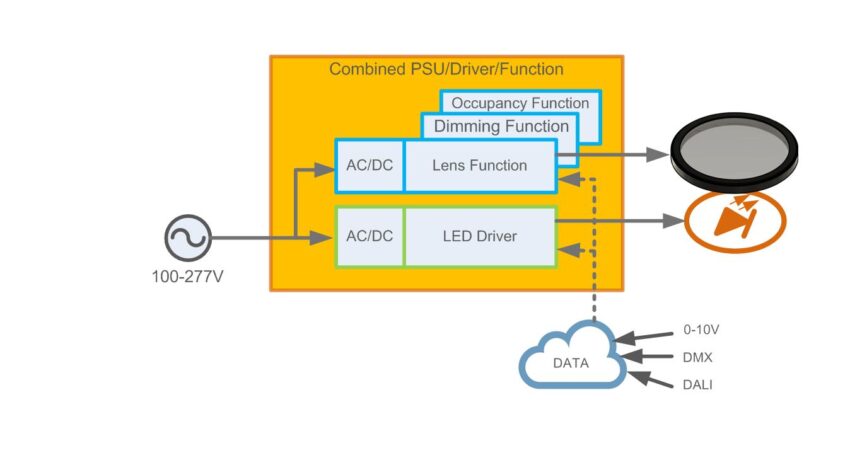

Power requirements are minimal and easily supplied by today’s drivers. Like other functions, including dimming, CCT tuning, etc., control functionality is required in addition to power. There are two common designs for providing this functionality.

The first option uses a power transformer to feed DC power to both the LED Driver and the Lens Function (or dimming or CCT tuning). From the combined driver/function ‘box’ power and control signals are sent to the LED and lens.

The lens function provides the correct variable amplitude square wave (VASW) that is used to control the focus and the lens’ dynamic beam shaping.

The second option utilizes a power supply that is integrated with the LED Driver and Lens Function. This is the design commonly supplied by companies including TCI, Tridonic, Osram, and Meanwell and simply incorporates the power supply with the driver and lens function.